Soybean High Consistency Processing

Genda has collaboration with the College of Food and Chemical Engineering at Shaoyang College to research on soybean processing in the Provincial Key Laboratory. Laboratory was established in May 2013, led by Professor Zhao Liangzhong. Focusing on the forefront of soybean products research with 4 main research directions: impact of soybean raw materials on the quality of soybean products, dynamics of soybean product quality changes, comprehensive utilization of soybean by-products, and new soybean processing technologies.

With a commitment to prioritizing technology, manufacturing and application, Genda applies high-consistency grinding technology to soybean processing. The HC grinding process adheres to the traditional Chinese stone grinding concept, preserving dietary fiber, enhancing output rates, and minimizing waste. Genda will engage in a deep collaboration to jointly drive technological innovation and product upgrades.

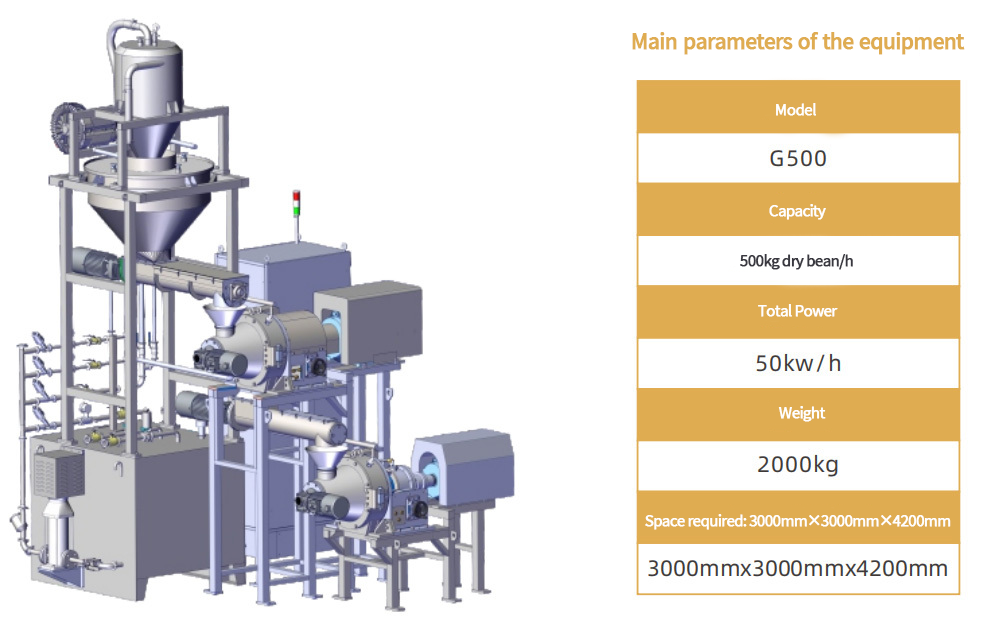

Main Equipment:

Product features:

(1) High output:

Compared with traditional LC refining, a lower mesh number is used. Part of the fiber participates in thermal gelation, which reduces the dregs rate by 25-35%, and increases the yield of tofu by 15-20%.

(2) High temperature refining:

The newly cooked pulp process can achieve through 100°C hot water grinding to remove the beany smell and improve the bean flavor. Pulp residue can separate by mill, which reduces the difficulty of separation process in the traditional cooked pulp method.

(3) Rich in dietary fiber:

Has higher dietary fiber content.

(4) The water holding performance is greatly improved:

Increase fine fibers and thus water-holding performance, tofu water leak is reduced.

(5) Yield increase:

Increasing yield of tofu by 30% and kept the same quality. Both firm tofu and soft tofu can be made.

(6) Increase the value of by-products:

Most of bean dregs have a particle size of 0.2-0.3mm, which can be used as raw materials for biscuits, pastries and other processed foods, increase material utilization and added value.

Processing and finished product comparison table

| Gypsum tofu comparison | Traditional tofu production equipment | Soybean High Consistency Grinding System |

| Refining gap | 0.1-1mmUnable to monitor in real time | 0.03mm visual control and adjustment |

| pulp separation | 100-150 mesh | 80 mesh |

| tofu yield(Calculated per kilogram of dry beans) | 1.5-2 kg soft tofu | 2-2.25 kg soft tofu |

| Slagging rate(In dry basis) | 20%-30% | 14%-18% |

| Brined and Physalis Tofu Comparison Project | Traditional tofu production equipment | Soybean High Consistency Grinding System |

| Refining gap | 0.1-1mmUnable to monitor in real time | 0.03mm visual control and adjustment |

| pulp separation | 120-150mesh | 80-120 mesh |

| tofu yield(Calculated per kilogram of dry beans) | 0.6-0.75 kg of dried tofu 1.25-1.4 kg of firm tofu | 0.75-0.85 kg of dried tofu 1.6-1.86 kg of firm tofu |

| Slagging rate(In dry basis) | 20%-30% | 16%-18% |