HC stock preparation for packaging paper

Packaging paper High Consistency Applications

Packaging paper that uses repeatedly recycled paper as raw material has limitations such as folding resistance, bursting resistance, ring pressure and other strength performance indicators that are difficult to guarantee. In large-scale production, it is necessary to add costly high-quality fibers and reinforcing chemical materials. To ensure the required strength of paper, the cost increases and the water system treatment becomes more challenging. The high-consistency beating system provided by Genda can solve this problem. We have cooperated with many paper mills and have completed the renovation of more than 30 production lines. Our supply covers the various customers’ needs of: innovative technology, reliability and operability, advanced automation solutions and general contracting engineering services. To ensure that our clients can improve paper performance and reduce operating costs while ensuring the smooth operation of the mill system.

Main equipment:

|

||

| Papermaking HC refining system | ||

|

||

| Main equipment of HC refining system | Dual-Drum Thickener | Screw Conveyor |

Process technology:

▌Advantages of applying HC refining to packaging paper:

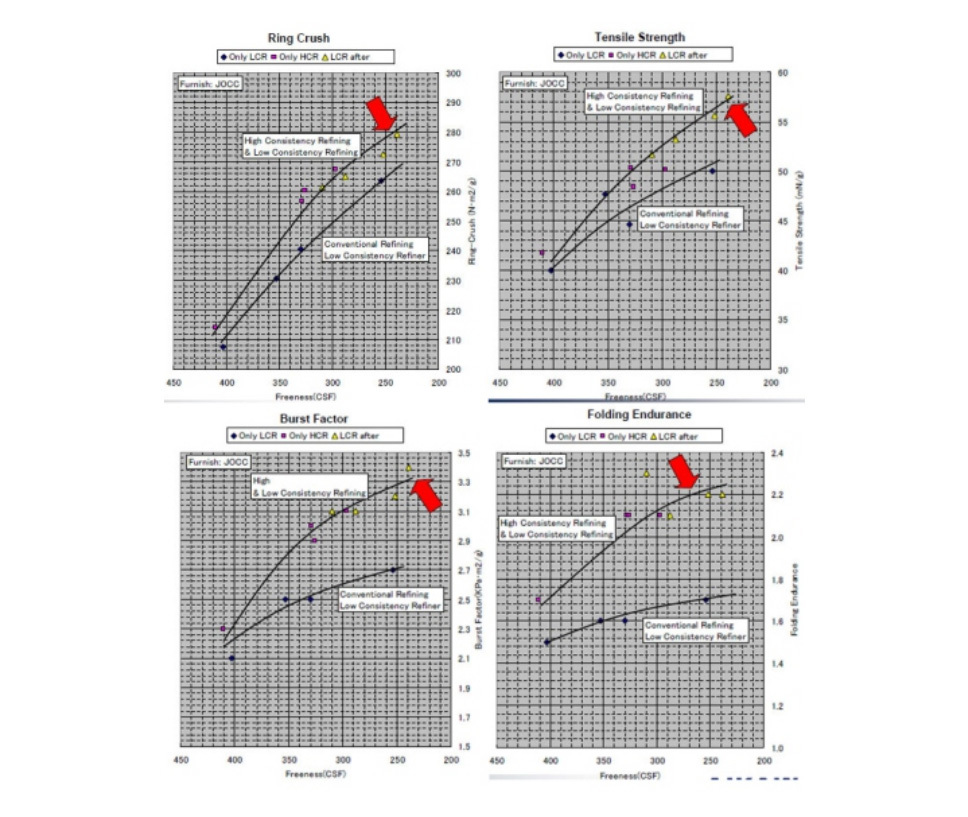

▌Effectively improve strength properties of paper including tear resistance, folding resistance, and ring pressure by 20~50%;

▌Improve internal bonding strength, improve stiffness and tightness, and reduce filling loss;

▌Reduce the consumption of imported recycled paper and chemicals while ensuring the same strength;

▌Compared with LC refining, the fiber retention rate is high, and the white water concentration under the wire is low, with a reduction range of 15~25%, which can effectively reduce production costs;

▌Compared with LC, due to the effective retention of fiber length and reduction of fine fibers, the fiber drainage performance is improved around 10%.

▌Increase paper machine speed by 1~5%;

▌Compared with LC refining, it can reduce the power consumption;

Solutions:

We value great importance to maintaining close cooperation with our customers, allowing us to develop targeted products and processes based on the raw materials and paper characteristics. To meet customers’ requirements for product improvement or cost reduction. We provide a package of solutions including process design, equipment selection and supply, advanced process control systems with one-click connection to front-end and back-end equipment, guided installation services, and line upgrade contracting engineering services.

Successful customer projects:

Project name: Sun Paper Containerboard Paper Machine No. 31, 32, 35, 36 HC refining upgrade Project

Time and location: 2018 Sun Paper Yanzhou, Shandong Province

Paper machine: Voith paper board machine with annual output of 600,000 tons

Customer demand: Stabilize folding resistance and improve bursting resistance

Solution: Provide two sets of Genda Fiber HCR1100 high consistency refining system

Implementation results: The folding resistance of containerboard paper has been stabilized (especially in winter), and the bursting resistance has increased by 20%.

Project name: Hengshan New Golden Dragon tube paper low-consistency refining upgrade projects (two sets).

Time and location: 2020 Hunan Hengshan

Supporting paper machine: 4800 single fourdrinier wire multi-cylinder paper machine

Customer Requirement: improve product quality

Solution: Provide two sets of Genda Fiber HCR1100 high consistency refining system

Implementation results: Product quality has reached Class B standards from Class C. The appearance quality has been significantly improved, mainly due to the reduction of pulp spots and dust spots; the interlayer bonding strength has increased by more than 100J, and the ring press strength has increased by 20%.