Corn Mill

Genda Precision Grinding has used its high-consistency refiner technology accumulated over 19 years to develop a special mill for corn milling, which is designed to destroy the combination between germ, fiber, starch, oil and protein, without making fibers cut too finely, resulting in a sharper separation between fiber and protein/starch/oil. Genda fine grinder grinds germ and kernels particles to a particle size of about 300-800 microns, while most fibers remain within the particle size range of 500-2000 microns. Achieve no greater than 50% by weight of the total particles having a particle size of 100 - 800 microns. In solid particles larger than 300 microns, protein is approximately 29.5%. After grinding, and if washing techniques are used, the protein in the fiber can be reduced from about 29.5% to about 21.1%. The oil in the fiber can be reduced from about 9.6% to 6.4%, and the starch in the fiber can be reduced from about 5.5% to 3%.

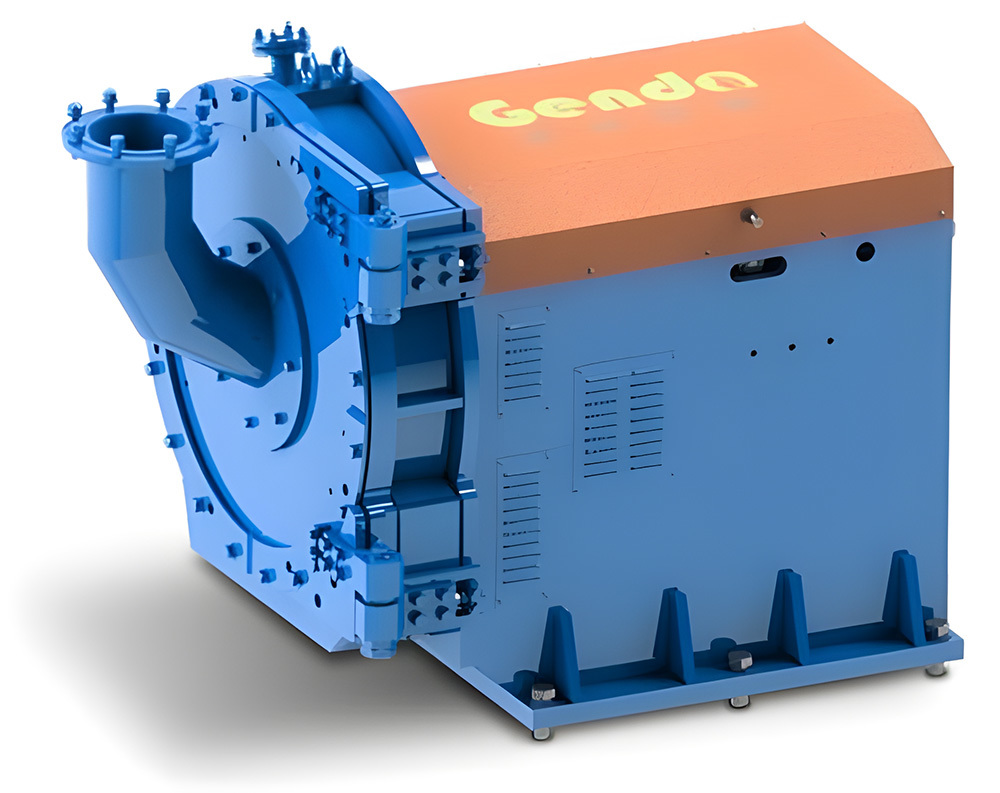

Main Equipment:

1、The main components of the grinder are: grinding chamber, main shaft assembly, frame, advancing and retracting tool mechanism, etc.

2、The grinder is driven by a servo motor, the gear set is driven by the reducer, and the thrust is distributed to lifting screws on both sides to ensure stable thrust and precise clearance control.

Successful customer projects:

Project: ICM Inc. corn mill

Time and location: July, 2022 ICM, St. Joseph, Missouri, USA

Customer requirement: Replace old mills and improve corn kernel wall breaking rate.

Solution: 920 Mill

Raw Material: Dried corn