Printing & Writing Paper

Technology, Application & Services for Printing & Writing Paper

Some printing & writing paper production is filled with calcium carbonate, resulting in low paper breakage. And due to the large price difference between CTMP and Kraft pulp, many paper mills hope to increase the amount of CTMP/APMP pulp to reduce raw material costs. However, the existing low-consistency refining of hardwood pulp or other short fibers has limited improvement in short fiber strength, making the paper strength performance not high enough. We use high-consistency refining to treat hardwood or other short-fibers pulp to improve strength, reduce the long-fiber pulp or kraft pulp ratio.

Main Equipment:

|

||

| Papermaking high consistency stock preparation complete system equipment | ||

|

||

| Papermaking high consistency stock preparation main equipment | Dual Drum Thickener | Feed Screw |

Processing Technology:

▌The advantages of applying high-consistency refining to Printing & Writing Paper:

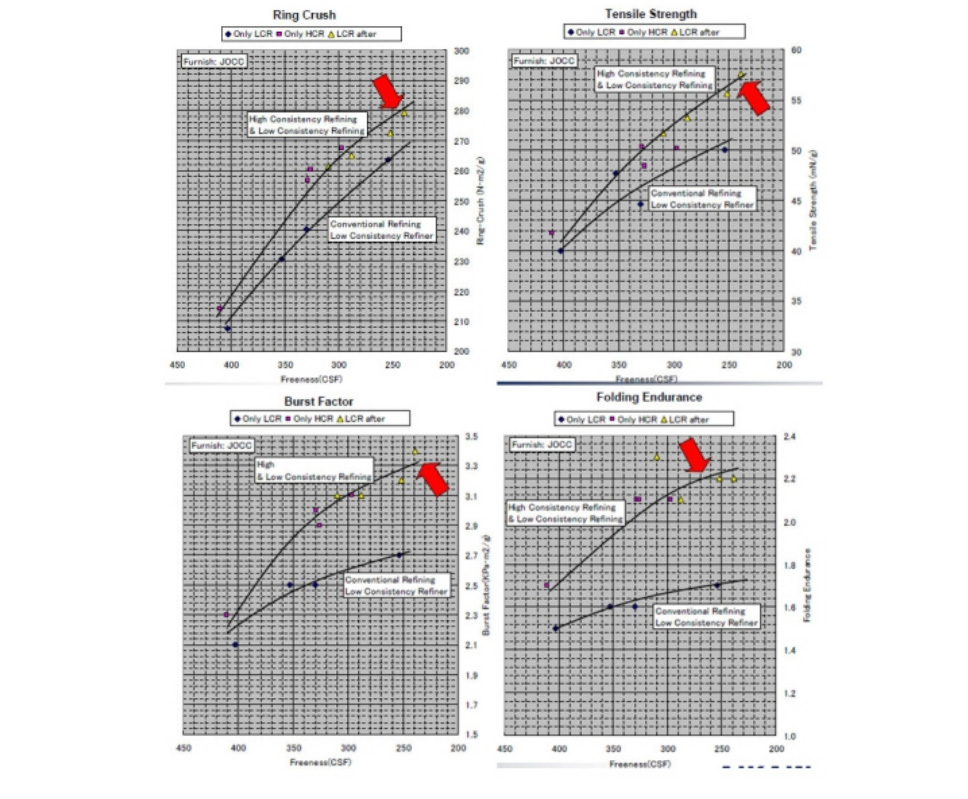

▌Can effectively improve paper tensile strength, tear strength, folding endurance and other strength properties, and reduce long fibers usage;

▌High fiber retention rate, low concentration of white water under the mesh, good water filterability, effectively reducing production costs;

▌Improve the bonding performance of fine fibers and long fibers, reduce the phenomenon of powder dust, and increase ash content;

▌It can soften fibers, increase bulk, and improve the printability of paper;

▌Under the same strength index, the beating degree can be reduced and power consumption can be saved;

Solutions:

We value a great importance to maintaining close cooperation with our customers, allowing us to develop targeted products and processes based on the raw materials and paper characteristics. To meet customers’ requirements for product improvement or cost reduction. We provide a package of solutions including process design, equipment selection and supply, advanced process control systems with one-click connection to front-end and back-end equipment, guided installation services, and line upgrade contracting engineering services.

Successful customer projects:

Project name: Chenming Paper LC to HC stock preparation transformation.

Time and Location: Hubei Province, Chenming Paper has 3 systems sets purchased from Genda since 2014.

Customer demand: processing reed pulp to produce anti-stick base paper

Solution: Supplied Genda HCR1100 high consistency refining system

Implementation results: Reduce long fiber ratio by 4-5%, the hand feel is significantly improved, paper machine's papermaking performance and post-processing performance are improved.