Tissue paper stock preparation

HC stock preparation technology, applications and services for hardwood pulp on Tissue paper

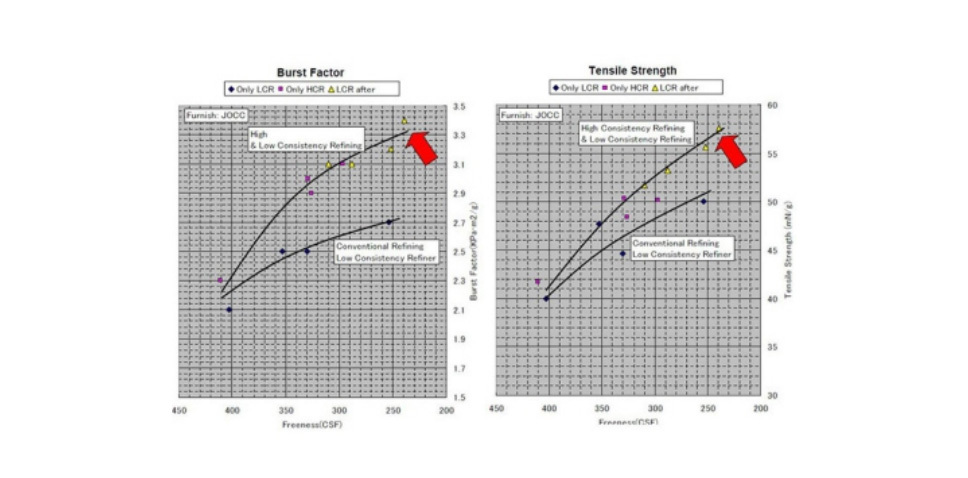

Tissue paper using hardwood and softwood pulp as raw materials has a higher long fiber ratio (usually ranging from 20-35%). When the price difference between long and short fiber averages $150 USD, it has increased cost to paper mills. When low-consistency refining is used to treat Hardwood, and light refining is generally used. Short fibers do not provide the strength required for paper; thus, long fibers ratio increased. The reason why heavy refining cannot be used: low-consistency heavy refining severely cuts the fibers. Although the tensile strength can be improved, the strength properties related to paper making and post-processing such as bursting and tearing cannot be guaranteed. This also causing loss of bulk. The high-consistency Refining system provided by Genda can solve this problem.

High-consistency refining process of hardwood pulp will not cause fiber cutting no matter how high the beating degree is. At the same time, the fiber twists and curls produced by HC refining can also maintain good bulk. Hardwood pulp can give full play to the strength properties of short fiber raw materials through HC refining. While maintaining various strength indicators and bulk, the long-fiber ratio can be reduced by 10-15, which greatly optimizes the customer's cost structure. At the same time, HC refining can also greatly improve the softness and surface smoothness of the paper. We have cooperated with many domestic customers and have completed the construction and renovation of more than 20 virgin wood pulp tissue production lines. Our supply covers the various needs of customers: innovative technology, reliability and operability, advanced automation, and turnkey engineering services to ensure paper performance and reduce operating costs, at the same time maintaining smooth system operation.

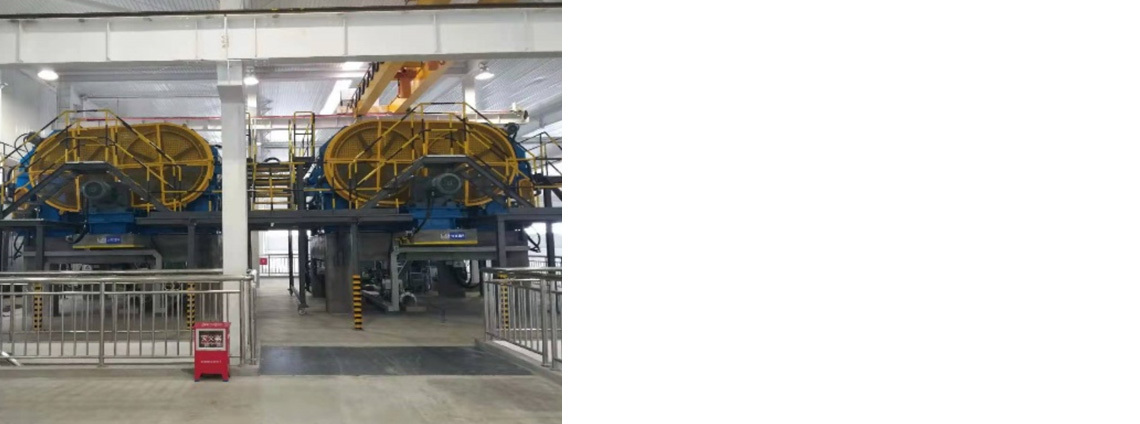

Main Equipment:

|

||

| Papermaking high consistency stock preparation complete system equipment | ||

|

||

| Papermaking high consistency stock preparation main equipment | Dual Drum Thickener | Feed Screw |

Process technology:

▌Advantages of HC refining to Tissue

▌It can effectively improve the tensile strength, tear strength and other strength properties by 10-20%

▌It can significantly improve softness, absorbency and bulk of Tissue paper

▌During the papermaking process, the fiber retention rate is high and the white-water concentration under the wire is low. The reduction range of 15-25% can effectively reduce production costs;

▌Improve the bonding performance of fine fibers and long fibers, and reduce the phenomenon of powder dust.

▌Due to the effective retention of fiber length and reduction of fine fibers, the fiber water filtration performance is improved by about 10% and the paper machine speed is increased by 1-5%;

▌Due to the ability to improve the softness of the fiber, the applicable range of the fiber can be greatly improved.

Solutions:

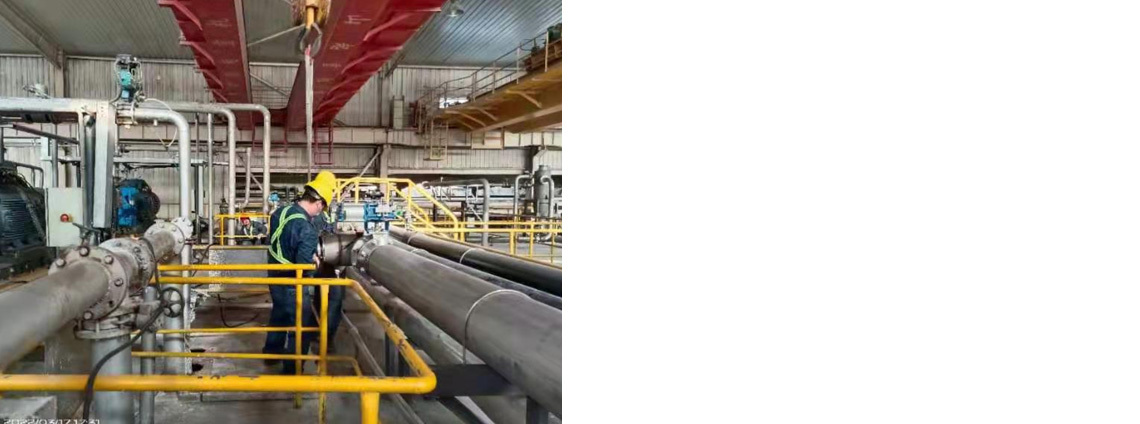

We maintaining close cooperation with our customers, allowing us to develop targeted high-consistency refining processes and stock preparation solutions based on the characteristics of different customers' Tissue paper varieties to meet the needs for product improvement or cost reduction. We provide a package of solutions including process design, equipment selection and supply, advanced process control systems with one-click connection to front-end and back-end equipment, guided installation services, and general contracting engineering services.

Successful customer projects:

Project name: Vinda Paper’s low-consistency pulping transformation to high-consistency pulping

Time and Location: 2018-2022 Hubei Vinda (five sets), Zhejiang Vinda (one set), Sichuan Vinda (one set), Shandong Vinda (two sets)

Supporting paper machine: Tesker 1600m 2800 paper machine

Customer demand: reduce long fiber ratio

Solution: 9 sets of Genda Fiber HCR1100 high-consistency Refining systems

Implementation results: Reduce long fiber ratio by 10-20%, the hand feeling is significantly improved, and the paper machine's papermaking performance and post-processing performance are improved.